Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

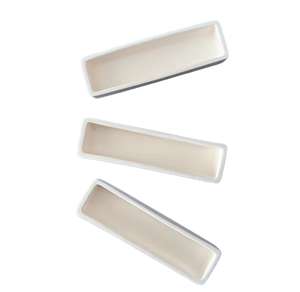

Overview of Alumina Boat

An alumina boat is a type of laboratory or industrial vessel made from high-purity alumina (Al₂O₃), a ceramic material known for its excellent thermal stability, high melting point, and chemical resistance. Alumina boats are primarily used in high-temperature applications where they can withstand extreme conditions such as those encountered in sintering, calcining, or melting processes. They are often used in furnaces or kilns for holding samples or materials during heat treatment processes.

Alumina Boat

Features of Alumina Boat

- High Temperature Resistance:

- Alumina boats can withstand temperatures up to 1600°C or higher depending on the specific material grade, making them ideal for high-temperature applications like sintering, calcining, and metal melting.

- Chemical Resistance:

- They have excellent resistance to most acids, alkalis, and organic solvents, which is beneficial in processes that involve aggressive chemicals.

- Thermal Shock Resistance:

- Alumina boats can handle rapid temperature changes without cracking or deforming, making them suitable for processes that require quick heating or cooling.

- High Purity:

- Most alumina boats have a purity level of 99.7% or higher, ensuring minimal contamination in processes requiring precise chemical compositions.

- Good Mechanical Strength:

- Alumina is a hard, durable material with good resistance to abrasion and mechanical wear, making the boats long-lasting and able to withstand handling in harsh environments.

- Customizable Designs:

- Alumina boats can be produced in various shapes (e.g., rectangular, round, square) and sizes, from small volumes (e.g., 10 mL) to large capacities (e.g., 500 mL or more), based on specific customer needs.

- Smooth Surface Finish:

- These boats often come with a smooth and polished surface, reducing the risk of contamination and making them easier to clean after use.

Specification of Alumina Boat

| Specification | Details |

|---|---|

| Material | Alumina (Al₂O₃) |

| Purity | ≥ 99.7% |

| Color | White or light beige |

| Density | 3.90 g/cm³ |

| Max Operating Temperature | 1600°C (depending on purity and design) |

| Melting Point | ~2050°C |

| Size | Customizable (e.g., 50mm x 100mm, 80mm x 150mm) |

| Wall Thickness | Typically 2-5 mm (depends on size) |

| Shape | Rectangular, Round, Square, or Custom Designs |

| Volume Capacity | Typically ranges from 10 mL to 500 mL |

| Thermal Shock Resistance | High (can withstand rapid temperature changes) |

| Surface Finish | Smooth, polished surface (varies based on manufacturer) |

| Resistance to Chemicals | Excellent resistance to acids, alkalis, and organic solvents |

| Applications | Sintering, melting, calcining, crucibles for high-temperature reactions |

| Weight | Varies based on size and design |

Applications of Alumina Boat

- Sintering:

- Used to hold materials in a furnace during the sintering process (a method of heat treating powdered metals or ceramics).

- Melting:

- Ideal for use as a crucible or container for melting metals, glass, or other materials due to their high thermal stability.

- Calcining:

- Employed in the heating of substances to high temperatures in the absence of air (or with controlled amounts of air) to induce a chemical change or phase transition.

- Heat Treatment:

- Used for the heat treatment of materials, such as in the production of advanced ceramics, semiconductors, or metal alloys.

- Sample Holding:

- Often used in laboratories to hold samples during experiments that require heating in a furnace or kiln.

- Catalyst Support:

- Some alumina boats are used in processes where the boat itself serves as a support for catalysts in chemical reactions.

- Metallurgical and Ceramic Applications:

- Used in both the metallurgy industry (e.g., for melting non-ferrous metals) and the ceramic industry (e.g., for sintering or calcining materials).

- Environmental and Chemical Research:

- Employed in laboratories for various high-temperature chemical reactions, including environmental testing and material degradation studies.

Company Profile

Alumina Technology Co., Ltd.! We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

FAQs of Alumina Boat

Alumina offers several advantages, including high-temperature resistance, excellent chemical inertness, low thermal expansion, and superior mechanical strength, making it a preferred choice in high-temperature applications compared to other materials like glass or plastic.

What is the maximum temperature an alumina boat can withstand?

Most alumina boats can withstand temperatures up to 1600°C. However, the exact temperature tolerance can vary based on the purity of the alumina and the specific design of the boat.

Can alumina boats be used in reducing atmospheres?

Yes, alumina boats can be used in both oxidizing and reducing atmospheres, but care must be taken depending on the specific process to ensure the material integrity is maintained.

How do I clean an alumina boat?

Alumina boats are generally easy to clean. A simple procedure involves rinsing with water or mild solvents to remove any residues. For stubborn stains or residues, high-temperature cleaning in a furnace may be necessary.

Can alumina boats be used for melting metals?

Yes, alumina boats are widely used as crucibles for melting metals, especially non-ferrous metals, due to their high-temperature resistance and chemical stability.

Are alumina boats reusable?

Yes, alumina boats are typically reusable. However, their lifespan may be affected by the conditions of use, such as the temperature reached, the type of material handled, and the frequency of use. Over time, surface wear or chemical degradation may occur, requiring replacement.

What is the difference between an alumina boat and an alumina crucible?

An alumina boat is generally a shallow, rectangular or boat-shaped vessel designed for holding or transferring materials during high-temperature processes. An alumina crucible, on the other hand, is usually a deep, bowl-shaped container used for melting or heating materials to their melting points, often with a lid for containment.

Can alumina boats be used for sintering ceramics?

Yes, alumina boats are often used in the sintering of ceramics because of their high purity, thermal stability, and ability to withstand high temperatures without reacting with the materials being processed.

What is the advantage of using alumina over other materials?

Alumina offers several advantages, including high-temperature resistance, excellent chemical inertness, low thermal expansion, and superior mechanical strength, making it a preferred choice in high-temperature applications compared to other materials like glass or plastic.

REQUEST A QUOTE

RELATED PRODUCTS

99.7 Al2o3 Alumina Ceramic Crucible Boat

Alumina ceramic boat

Laboratory Use Alumina Combustion Boat Al2O3 Sagger Porcelain Boat Ceramic Cupel in Lab

Custom Alumina Ceramic Cylinder Part 99% Al2O3 Alumina Combustion Boat , Rectangle Alumina Ceramic Boats Crucible

Custom 99% High Purity Al2o3 Alumina Combustion Boat With Lid Alumina Ceramic Par Rectangle Alumina Ceramic Boats Crucible