Professional Premium Aluminum Oxide Products Supplier

The global need for lightweight, long-lasting, and aesthetically functional building products has actually risen exponentially, placing lightweight aluminum composite products (ACM) as a cornerstone of contemporary architectural advancement. As the globe continues to urbanize at an extraordinary price, there is an enhancing demand for building and construction products that are not only solid and resilient but also eco-friendly and economical. In reaction to these demands, our firm specializes in sophisticated building options made to satisfy the evolving demands of designers, designers, and builders around the globe. Our newest offerings in aluminum composite panels (ACP), aluminum composite boards, and aluminum panel composite systems are redefining sector criteria, dealing with jobs spanning high-rises, green facilities, and high-performance transportation systems.

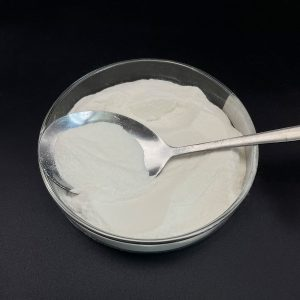

aluminum composite material

Aluminum composite panels have emerged as a leading option for engineers and designers due to their exceptional strength-to-weight ratio, rust resistance, and thermal performance. These residential or commercial properties make them excellent for usage in a variety of applications, from outside cladding on buildings to indoor dividings and signs. Recent advancements in PVDF (polyvinylidene fluoride) and polyester coverings additionally boost their fireproofing and UV-resistant homes, making them appropriate for use in severe environments. For instance, our 4mm ACP sheets with 0.3 mm lightweight aluminum layers are engineered to stand up to rough environmental stressors while keeping a streamlined, modern finish– best for high-rise exteriors and urban renewal projects. Additionally, the integration of these sophisticated finishes permits better layout adaptability, enabling designers to produce visually striking exteriors that stand the test of time without jeopardizing safety and security or performance.

The adaptability of aluminum composite products prolongs much beyond standard building and construction applications. The automotive and marketing industries are significantly adopting aluminum composite boards for their lightweight yet durable qualities. In automobile manufacturing, making use of ACPs can lower vehicle weight by up to 30%, directly straightening with rigorous Company Average Fuel Economy (COFFEE SHOP) gas efficiency requirements established for 2025. This decrease in weight contributes to boosted fuel performance and reduced discharges, assisting car manufacturers in fulfilling regulative demands while boosting automobile performance. At the same time, electronic printing on 3mm ACP boards has actually reinvented outside signs, offering vivid, weather-resistant display screens for international brand names. Personalized density options (ranging from 2mm to 6mm) and anti-bacterial layers additionally make these boards a hygienic option for medical care and hospitality insides, where tidiness and sturdiness are paramount.

Furthermore, the versatility of aluminum composite materials makes them an appealing alternative for short-lived frameworks and modular buildings. Their ease of installment and capability to be dismantled and recycled make them suitable for occasions, exhibits, and even calamity relief real estate. As the global population becomes extra mobile, the need for quick-to-assemble, lasting homes will certainly continue to grow, additionally driving the fostering of ACMs across numerous markets.

To showcase cutting-edge technologies and foster collaboration within the industry, our group proactively joins significant trade conventions and exhibits around the world. One such event is Aluminium U.S.A. 2025, which will certainly occur on May 28– 29 in Nashville. This premier gathering unites leaders in aerospace, building and construction, and sustainable material scientific research, supplying a platform to highlight advancements like aluminum panel composite systems with A2 fire scores. These systems are specially developed to satisfy stringent safety policies for high-risk settings such as flight terminals, data facilities, and other essential facilities. Attendees at Aluminium U.S.A. 2025 will certainly have the opportunity to discover real-time presentations of our self-cleaning nano-coated ACPs, which are engineered to reduce upkeep costs for high-rise building exteriors substantially.

By including nanotechnology in the finishing procedure, these panels can repel dirt, grime, and pollutants, consequently expanding the life span of the framework’s exterior and reducing the requirement for consistent cleansing.

Moreover, we are committed to establishing critical collaborations with principals in the structure market, including representatives, specialists, and innovation businesses. Via these collaborations, we intend to increase the advancement and implementation of cutting-edge ACM services that attend to the unique difficulties handled by different areas and market segments. For instance, by functioning carefully with local government and city organizers, we can personalize our items to fulfill details ecological and sustainability objectives, ensuring that each project adds favorably to its bordering location.

Budget-friendly rates remain a vital lorry chauffeur for worldwide purchase choices, especially in massive structure tasks where expenditure savings can be considerable. We provide a range of price options to fit different budgets and task specifications. Mass orders of aluminum composite panels begin at simply $2.3–$ 2.5 per square meter for 100m ² minimum order quantities (MOQs), making them an affordable alternative for smaller-sized jobs or those needing custom-made styles. Costs fire fire-resistant variants, which include innovative flame-retardant modern technologies, range between $10–$ 25/m ², providing improved safety attributes for high-risk applications. For large facilities tasks, we give tailored options such as 6mm honeycomb-core panels at $25–$ 35/m TWO, incorporating architectural stability with acoustic insulation to create comfy and protected indoor settings.

Furthermore, our commitment to cost-efficiency extends beyond preliminary acquisition rates. By purchasing long-lasting, resilient materials, clients can accomplish significant cost savings over the lifecycle of their projects. Reduced maintenance expenses, energy-efficient styles, and expanded product lifespans all contribute to a lower overall price of possession, allowing designers to allot resources better and focus on delivering premium projects that go beyond assumptions.

With LEED-certified jobs dominating metropolitan growth, our environment-friendly ACPs– crafted from 70% recycled aluminum– are gaining grip amongst eco-conscious developers. Using recycled materials not only lowers waste but also reduces the carbon impact associated with production. Innovations such as oxide-film laminates and a lot more boost the sustainability profile of our items, not simply lowering eco-friendly influence but also broadening product lifespans to 25+ years. This durability is critical in today’s hectic structure sector, where the stress of building quickly commonly comes with the expenditure of top quality and durability. By focusing on green structure principles, we make sure that our items straighten with round economic climate principles, advertising and marketing accountable usage and manufacturing practices throughout the supply chain.

Looking in advance, the ACM market is placed for significant advancement, with projections estimating an evaluation of $9.65 billion by 2030. To remain ahead of this promptly progressing landscape, we continue to be fully committed to research and development, constantly discovering new approaches to boost the effectiveness, sustainability, and cost of our products. With close teamwork with consumers, we can supply tailored solutions that meet their distinct demands and difficulties, assuring that every task gains from the current improvements in aluminum composite technology.

To conclude, as the worldwide structure and construction market experiences placing stress on innovation and change, lightweight aluminum composite products represent a promising choice for a number of the field’s essential troubles. With their unmatched mix of strength, convenience, and sustainability, ACMs are well-positioned to play a central responsibility fit the future of style and design. By accepting these transformative modern technologies, stakeholders can accomplish unequaled efficiency, safety, and design flexibility, leading the way for a brighter, more lasting future.

Supplier

Alumina Technology Co., Ltd focus on the research and development, production and sales of aluminum oxide powder, aluminum oxide products, aluminum oxide crucible, etc., serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services. If you are looking for high quality aluminum composite material, please feel free to contact us. (nanotrun@yahoo.com)

Tags: aluminium composite panel,aluminium composite board,aluminium panel composite