Professional Premium Aluminum Oxide Products Supplier

Aluminum oxide plate, made of aluminum oxide (Al2O3), is an advanced ceramic material known for its excellent performance. These boards have high hardness, excellent wear resistance, and outstanding thermal stability, making them indispensable in industries such as aerospace, automotive, electronics, and chemical processing. In addition, alumina ceramic plates have excellent electrical insulation properties, which enhances their applicability in electronic components and semiconductor packaging.

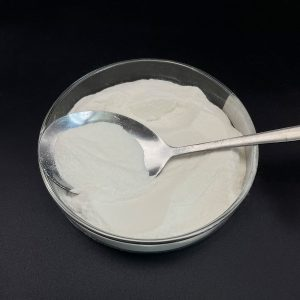

Aluminum oxide plate

A prominent feature of aluminum oxide plates is their chemical inertness, which allows them to withstand exposure to harsh chemicals without degradation. This characteristic makes aluminum oxide plates very suitable for environments where corrosion resistance is crucial, such as chemical reactors and laboratory equipment. In addition, the ability of alumina ceramic plates to maintain dimensional stability at high temperatures ensures their reliable performance in demanding applications such as furnace linings and refractory materials.

Specification of Alumina Plate

| Parameter | Description |

| Material Composition | High-purity alumina (Al<sub>2</sub>O<sub>3</sub>), content ≥ 99.5% |

| Density | 3.95 g/cm³ ± 0.05 g/cm³ |

| Mohs Hardness | 9.0 |

| Flexural Strength | ≥ 380 MPa |

| Compressive Strength | ≥ 2000 MPa |

| Fracture Toughness | 3.0 – 4.0 MPa·m<sup>1/2</sup> |

| Thermal Conductivity | 25 W/m·K (at room temperature) |

| Coefficient of Thermal Expansion | 7.5 × 10<sup>-6</sup>/°C (20-1000°C) |

| Maximum Service Temperature | Up to 1750°C |

| Dielectric Constant | 9.8 – 10.1 (1 MHz, 20°C) |

| Dielectric Loss | < 1 × 10<sup>-4</sup> (1 MHz, 20°C) |

| Volume Resistivity | > 10<sup>14</sup> Ω·cm (20°C) |

| Water Absorption | ≤ 0.01% |

| Surface Roughness | Ra ≤ 0.8 μm |

| Size Range | Standard size: 100mm x 100mm x 1mm – 50mm<br>Custom sizes available |

| Tolerance | ±0.1 mm or as per customer requirements |

| Color | White or light gray |

| Surface Finish | Polished, matte, sandblasted, etc. |

Porous aluminum oxide plate: special applications

Porous alumina plate represents a special form of alumina ceramic, providing unique advantages for filtration and catalytic processes. The porous structure allows for effective gas and liquid separation, making these plates of immeasurable value in air purification systems, water treatment plants, and membrane technology. In addition, the high surface area of porous alumina plates enhances their catalytic activity, making chemical reactions in industrial processes more efficient. The demand for sustainable and environmentally friendly technologies has driven the development of porous alumina sheets. These materials play a crucial role in reducing emissions and improving resource efficiency, consistent with global efforts to address climate change and promote green practices. For example, porous alumina filters can remove harmful particulate matter from exhaust gases, helping to improve air quality and reduce environmental impact.

Comparison between aluminum oxide plate and silicon nitride (Si3N4)

Thermal conductivity

Aluminum oxide plate: Aluminum oxide has moderate thermal conductivity, sufficient to meet many applications, but not as high as silicon nitride. In situations where controlled heat dissipation is required, this characteristic may be advantageous.

Silicon Nitride (Si3N4): Si3N4 has higher thermal conductivity, making it an ideal choice for high-power electronic devices and heat sinks that require rapid cooling.

Mechanical strength and toughness

Oxidized aluminum plate: Oxidized aluminum plate is known for its high hardness and wear resistance, but its fracture toughness is lower compared to silicon nitride. This makes them more prone to brittle failure under certain stresses.

Silicon nitride (Si3N4): Si N ₄ exhibits excellent fracture toughness and can better resist crack propagation. This feature enhances its durability under dynamic load conditions.

Chemical stability

Aluminum oxide plate: Aluminum oxide has excellent chemical stability, especially in corrosive environments. It resists the erosion of many acids and alkalis, making it suitable for aggressive chemical processing.

Silicon Nitride (Si3N4): Although Si3N4 also exhibits good chemical stability, it may degrade at high temperatures in strong oxidizing atmospheres.

Handling complexity

Aluminum oxide plate: Compared to silicon nitride, the synthesis and processing of aluminum oxide plate are usually less complex. High-purity alumina powder helps to produce dense and high-quality ceramics through traditional methods such as sintering and hot pressing.

Silicon nitride (Si3N4): Due to the easy decomposition of Si N ₄ at high temperatures, more complex processing techniques are required. However, advances in manufacturing have increased the feasibility of producing high-performance silicon nitride ceramics.

Environmental impact

Aluminum oxide plate: From an environmental perspective, aluminum oxide has fewer issues with toxicity and disposal. Its stable properties reduce the risk of harmful emissions during manufacturing and disposal processes.

Silicon Nitride (Si3N4): Although Si 3 N ₄ is also considered environmentally friendly, the energy-intensive processes required for its production may result in a higher carbon footprint.

In summary, aluminum oxide plates (whether solid or porous) represent a key advancement in materials science, providing unique properties that meet modern engineering and sustainability needs. By comparing aluminum oxide plates and silicon nitride (Si3N4), we have gained valuable insights into their respective advantages and limitations, guiding informed decisions in material selection. As global policies continue to prioritize sustainability and innovation, the adoption of aluminum oxide sheets will undoubtedly play a key role in achieving long-term environmental and economic goals.

Supplier

Alumina Technology Co., Ltd focus on the research and development, production and sales of aluminum oxide powder, aluminum oxide products, aluminum oxide crucible, etc., serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services. If you are looking for high quality Aluminum oxide plate, please feel free to contact us. (nanotrun@yahoo.com)

Tags: alumina plate、alumina ceramic plate、aluminum oxide ceramic plate、porous alumina plate