Professional Premium Aluminum Oxide Products Supplier

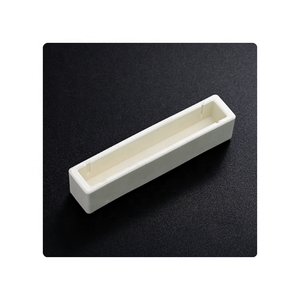

Alumina Boat

95% Alumina Sagger Crucible Ceramic Boat with Lid Product with Insulation Applications

High-temperature Melting Experimental Crucible 99.7 Al2o3 Alumina Ceramic Crucible Boat

Alumina Box Ceramic Boat Sagger

Alumina Combustion Ceramic Boat for High Temperature Furnace

1600degrees High Temperature Resistant 5ml Alumina Ceramic Evaporating Boat

Alumina ceramic boat

60x30x20mm Customized 99.7% Alumina Corundum Ceramic Boat Melting Crucibles

Lab High Purity 99% Al2O3 Rectangle Alumina Ceramic Boat 1700 C for Metal Casting and Ceramic Sample Preparation

Custom Rectangle Shape Alumina Ceramic Boat

Good Quality Unglazed Porcelain Ceramic Combustion Boats With Alumina Ceramic Material

95% 99% Alumina Crucible Boat Al2O3 Ceramic Boat

C795 95% Aluminum Oxide Al2O3 Alumina Ceramic Combustion Boat for 1400C Furnace Industrial Ceramic Parts Custom Cutting Services

Alumina Ceramic Boat Products

Alumina ceramic ship products are a class of high-performance ceramic materials made of high-purity alumina (Al₂O₃) as the main raw material through a specific process. Its application in the marine industry is mainly reflected in the production of wear-resistant and corrosion-resistant components. These materials are widely used in applications with demanding material requirements due to their excellent physicochemical properties, such as high strength, high hardness and good thermal stability. In shipbuilding, the use of alumina ceramics can effectively extend the service life of ship components, reduce maintenance costs, and improve operational efficiency. In addition, with the development of science and technology, the application scope of alumina ceramics is also expanding, gradually penetrating into more fields.

Advantageous features of alumina ceramic ship products

Alumina ceramic boat products have many advantageous features that make them one of the ideal choices for modern marine engineering. Firstly, they have extremely high hardness and abrasion resistance, which can resist the influence of various abrasion factors in seawater and marine environment, thus significantly extending the service life of the products. Secondly, the material exhibits excellent corrosion resistance, with excellent resistance to acids, alkalis, salts and other media, ensuring stable long-term performance. Furthermore, alumina ceramics demonstrate good thermal shock resistance and high temperature stability, maintaining structural integrity even under extreme temperature changes. In addition, these products are lightweight and less dense, helping to reduce the burden on the hull and improve sailing speed and fuel economy. Finally, they are easily machined into complex shapes to meet the needs of different applications.

Specifications of Alumina Ceramic Marine Products

| Parameter | Specification |

|---|---|

| Material Composition | High-purity alumina (Al₂O₃) with a purity level ≥99.5% |

| Hardness | Vickers hardness HV ≈ 1800-2200 |

| Density | Theoretical density up to 3.97 g/cm³, actual density depends on the production process |

| Flexural Strength | Room temperature flexural strength >350 MPa |

| Compressive Strength | Room temperature compressive strength >3000 MPa |

| Thermal Conductivity | Typically ranges from 20 to 30 W/m·K at room temperature |

| Coefficient of Thermal Expansion | Approximately 7.5 × 10⁻⁶ /°C over the range 25°C to 1000°C |

| Dielectric Constant | Low dielectric constant, typically around 9-10 |

| Corrosion Resistance | Excellent resistance against seawater, acids, bases, and salts |

| Operating Temperature Range | Suitable for continuous operation in environments from -269°C to +1700°C depending on application |

Production Process of Alumina Ceramic Boat Products

The production of alumina ceramic boat products is a complex and delicate process, mainly including the following key steps: first, the selection and preparation of raw materials, the need to select high-purity alumina powder as the basic raw materials, while adding the appropriate amount of auxiliary components to improve the molding performance or to enhance some of the characteristics of the final product. Next is the preparation of billet, the mixed powder will be pressed into the required shape of billet by dry pressing, isostatic pressing, etc.; then drying treatment to remove the moisture in the billet, to ensure that the subsequent processes are carried out smoothly. Next is the sintering stage, which is the core link in determining the quality of the product. It is heated in a high-temperature furnace to a state near the melting point, but not completely melted, so that the solid-phase reaction between particles occurs and is tightly bound together to form a dense body. Finally, the finished products are tested and post-treated, such as dimensional accuracy checking, surface polishing, etc., to ensure that each ex-factory product meets the strict quality standards.

Application areas of alumina ceramic ship products

Alumina ceramic boat products find a wide range of applications in several fields due to their unique physical and chemical properties. In the marine manufacturing industry, they are mainly used to manufacture pump and valve components, seals, bearings and other wear parts, as these parts are often exposed to harsh working environments, such as high pressure, highly corrosive liquids and severe friction. In addition, alumina ceramics are also used to manufacture key components in navigation equipment, such as compass bowls and gyroscope mounts, because their non-magnetic properties do not interfere with the normal operation of sensitive instruments. For ocean exploration, the material can be used to make sonar transmissive windows, using its low dielectric constant and high mechanical strength to optimize signal transmission. For deep-sea oil platforms, alumina ceramics can be used to build protective coatings or as special tooling materials to withstand the effects of high subsea pressures and corrosive seawater. In short, with its superior performance, alumina ceramics provide reliable solutions for marine engineering and promote the progress and development of related technologies.

Company Profile

Alumina Technology Co., Ltd.! We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Alumina Ceramic Boat Products

Q: Are alumina ceramic boat products suitable for all types of boats?

A: Alumina ceramic ship products are particularly suitable for vessels that operate in harsh environments, such as ocean-going cargo ships, fishing fleets and marine research vessels. However, specific suitability needs to be evaluated based on the specific needs and technical parameters of each vessel.

Q: Does the installation of alumina ceramic ship products require specialized skills?

A: Yes, in order to ensure optimum performance and safety, it is recommended that the installation be carried out by specially trained technicians in accordance with the instruction manual provided by the manufacturer.

Q: Can alumina ceramic boat products withstand extreme temperature changes?

A: Alumina ceramics have excellent resistance to thermal shock and can remain stable over a wide temperature range, making them suitable for marine environments that experience frequent temperature changes.

Q: What is the service life of alumina ceramic marine products?

A: It depends on the specific conditions of use and maintenance, but ideally, alumina ceramic products can provide durability and longer service life than traditional metal materials.

Q: How cost-effective are alumina ceramic boat products?

A: While the initial investment may be high, in the long run, alumina ceramic products can provide significant cost savings due to less frequent repairs and longer replacement intervals.