Professional Premium Aluminum Oxide Products Supplier

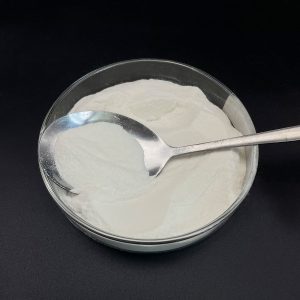

Nano Alumina Powder

A Brief Overview of Aluminum Oxide Nanopowders

Alumina nanopowder (Al₂O₃) is an alumina material with particle size in the range of 1 to 100 nanometers. This ultrafine powder plays an important role in modern technology due to its unique physical and chemical properties. Alumina nanopowder possesses an extremely high specific surface area, which gives it excellent catalytic activity, adsorption properties, and biocompatibility. In addition, its high hardness, high melting point, and good electrical insulation and chemical stability make it ideal for many high-tech applications. The development of nanotechnology has promoted the wide application of nano alumina in the fields of new materials, electronic devices, pharmaceutical carriers, etc., and promoted the technological innovation of related industries.

Advantageous features of nano alumina powder

Nano alumina powder shows a series of excellent characteristics by virtue of its tiny particle size. Firstly, due to its huge specific surface area, nano alumina exhibits significantly enhanced reactivity, which makes it an ideal candidate for efficient catalysts. Second, nanoscale alumina particles can increase the strength and toughness of materials, which can significantly improve mechanical properties when added to composites. Further, nanoscale alumina has excellent thermal stability and corrosion resistance, even in extreme environments. In addition, it has excellent optical transparency and UV shielding ability, which makes it suitable for manufacturing transparent protective coatings. Finally, nano alumina powder is easily dispersed and can form a uniform distribution in liquid or solid matrices, thus enhancing the overall performance of the final product.

Specifications Table for Nano Alumina Powder

| Parameter | Specification |

|---|---|

| Material Composition | High-purity alumina (Al₂O₃) |

| Particle Size | 10 - 100 nm |

| Purity Level | ≥99.9% |

| Surface Area | >50 m²/g |

| Density | ~3.97 g/cm³ (bulk density varies) |

| Morphology | Spherical or irregular particles |

| Color | White |

| Thermal Stability | Excellent, stable up to 1800°C |

| Electrical Insulation | Good |

| Chemical Resistance | Excellent, inert to most chemicals |

| Packaging | Vacuum-sealed bags, suitable for long-term storage |

Production Process of Aluminum Oxide Nanopowder

The preparation of alumina nanopowders involves a variety of complex processes including, but not limited to, sol-gel, precipitation, vapor phase deposition, and hydrothermal synthesis. The first step is the selection of raw materials, usually pure aluminum salts are chosen as precursors. This is followed by a solution preparation stage where the precursor is dissolved in a suitable solvent and the solution properties are controlled by adjusting the pH and other parameters. For some methods, this is followed by sol-gel formation, where the solution is gradually converted to a viscous sol by the addition of a complexing agent. This is followed by a gelation process, where the sol solidifies into a wet gel with a three-dimensional network structure as the water evaporates. The drying process removes the water from the gel to form a dry gel. The final step is high-temperature sintering, in which the dry gel decomposes and reorganizes into pure alumina crystals under strictly controlled atmosphere and temperature conditions. This process also involves steps such as crushing and grading to ensure that the desired particle size distribution is obtained. The finished product is also subjected to quality tests to ensure its purity and properties.

Applications of Aluminum Oxide Nanopowder

Aluminum oxide nanopowder is widely used in various fields due to its unique properties. In the electronics industry, it is used as a thermally conductive filler to enhance the thermal performance of plastic, rubber and ceramic substrates while maintaining electrical insulation. Aluminum oxide nanoparticles are also an important component of high-performance abrasives for precision polishing of semiconductor wafers and other precision components. In the medical industry, alumina nanopowder is used to make artificial bones and teeth because of its better compatibility with human tissue. In addition, alumina nanopowder can be used as a drug carrier for targeted therapy. In environmental protection, it can effectively remove heavy metal ions and organic pollutants from wastewater. In the coatings and cosmetics industry, nano-alumina provides anti-UV protection and increases product gloss. In short, with its versatility and adaptability, nano alumina powder is expanding into new application scenarios.

Company Profile

Alumina Technology Co., Ltd.! We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs on Aluminum Oxide Nano Powder

Q: Is nano aluminum oxide powder harmful to human body?

A: Aluminum oxide nanopowder itself is relatively safe, but inhalation of dust should be avoided during use, as long-term exposure may cause irritation to the respiratory tract. Therefore, appropriate protective equipment should be worn during operation.

Q: How does the particle size of alumina nanopowder affect its performance?

A: The smaller the particle size, the larger the specific surface area of alumina nanopowder, which increases its reactivity, adsorption capacity and mechanical strength. However, too small a particle size may lead to agglomeration problems and affect dispersibility.

Q: Can nano alumina powder withstand high temperatures?

A: Alumina nanopowders have a high melting point, typically over 2000°C, so they can remain stable in high temperature environments and are suitable for applications that require high temperature resistance properties.

Q: Are alumina nanopowders suitable for all types of composites?

A: Aluminum oxide nanopowders can improve the performance of most composites, but compatibility with other components and potential chemical reactions need to be considered for specific applications.

Q: What are the main factors affecting the price of alumina nanopowders?

A: The price depends on factors such as production process, purity grade, particle size and bulk purchase quantity. Advanced preparation techniques and high purity products usually cost more.